My goal is to educate the people of the United States about Sardinia’s beauty, her people, traditions, and arts, especially that of the weavers. When these exist as well-rooted foundations, it is easier to sell products at a good price and maintain the region’s economy within Sardinia itself.

I plan to meet with as many weavers, artists, and those who work in this field as possible, to open and maintain a permanent dialog.

Sardinia is blessed with a culture and diverse forms of art that should be respected, maintained, and protected. The preservation and elevation of the Sardinian arts, and, in particular, the art of the hand weavers is of fundamental importance: the respect for the handweavers will serve to open doorways of awareness and respect for all weavers, all their arts, and the heritage and culture of Sardinia. This, over time, will bring positive returns for all those working in tourism and commerce.

The art of handmade Sardinian textiles is important for many reasons. The art is almost lost. The manner in which Sardinian weavers work and live, their principles, and there awareness represent a heritage that can only have a great appeal for a population that lives in a high-tech world and suffers very high levels of stress. For those living in such conditions, the hand weavers become role models for more genuine lifestyle.

At this point in time, Sardinian textiles and designer are almost unknown, and rarely found outside of the island. This offers many opportunities. However, the prevailing idea is that Sardinian weavers are exclusively rug producers, not artists. It’s imperative that this perception change.

In recent years, we have heard too many stories of traditional cultures and their arts that have been appropriated by vendors who are greedy and lack scruples. Stolen designs are used to generate profit for large international conglomerates instead of the communities from which the designs come and items are traditionally produced.

The large companies from rich countries seek unique designs and unusual textiles to sell. The weavers of the “newly discovered” countries are happy — at least initially.

But then, the local weavers try to satisfy the growing demand by using powerlooms and opening mills. The focus becomes the quantity of production, sales volume, and profit. The weavers become producers and lose their identities as artists. Unfortunately, in this process, the respect for designs, the artists, and the art itself is lost.

This is the path of decline for the art and the economy. The worth of textiles and those who produce them declines. When the weavers become merely producers, their designs and their textiles become only commodities. When the designs and the weavers are not respected and protected, the international conglomerates and interior designers award contracts to the lowest bidders. They follow simple mathematics, the law of supply and demand. In the global economy, the lowest bidders will never be Sardinians. I certainly hope that Sardinian weavers will never try to compete with China, which will always win the low-cost competition.

In Chile, the traditional weavers began to weave with powerlooms to increase their production and satisfy the growing foreign demand. In the process, the weavers and their art were not respected or protected. The corporations of the United States and Europe stole designs from Chile to make clothes, accessories, and furniture in China. The Chilean weavers and factories were not able to compete with the corporations, and lost their art and their means of income.

A similar situation happened in Kenya. Today, all the textiles of traditional design in Kenya are made in China and imported into Kenya. I think there’s only one factory left in Kenya, and it’s owned by the Chinese.

Certainly we don’t want the corporations or other countries to profit from Sardinia in the same manner.

Instead, as the indigenous population of New Zealand, the Maori, and the traditional weavers of Guatemala (who have a tradition and designs similar to the weavers of Nule) have done to successfully fight and reclaim and protect their traditional arts, Sardinians should take steps to protect their culture.

In Sardinia, sellers don’t make a distinction between textiles made by hand, powerloom, or mill. In the tourist shops, on the internet, and even in some textile studios, all of these textiles are sold as “traditional” and “traditional handmade”.

For the purpose of elevating the esteem and value for their art, Sardinian weavers should be recognized as artists, and their traditional designs should be respected as art of Sardinian origin. Items which incorporate Sardinian designs should be made only by local producers. The protection of Sardinian artists and designs will be advantageous to all the weavers of the island.

Just as the European Union recognizes different classifications of traditional food, it’s important that Sardinian textiles are classified accurately with reference to the method and place in which they are made, and that the public be educated to this regard. In fact, all the classifications have their place and their buyers.

Having discussed and exchanged ideas and opinions with experts over the past years, I think that this system of classification will help buyers understand the classifications of textiles bearing the label “Made in Sardinia”, increase the esteem of all weavers of all the classifications, and protect the weavers in the global economy.

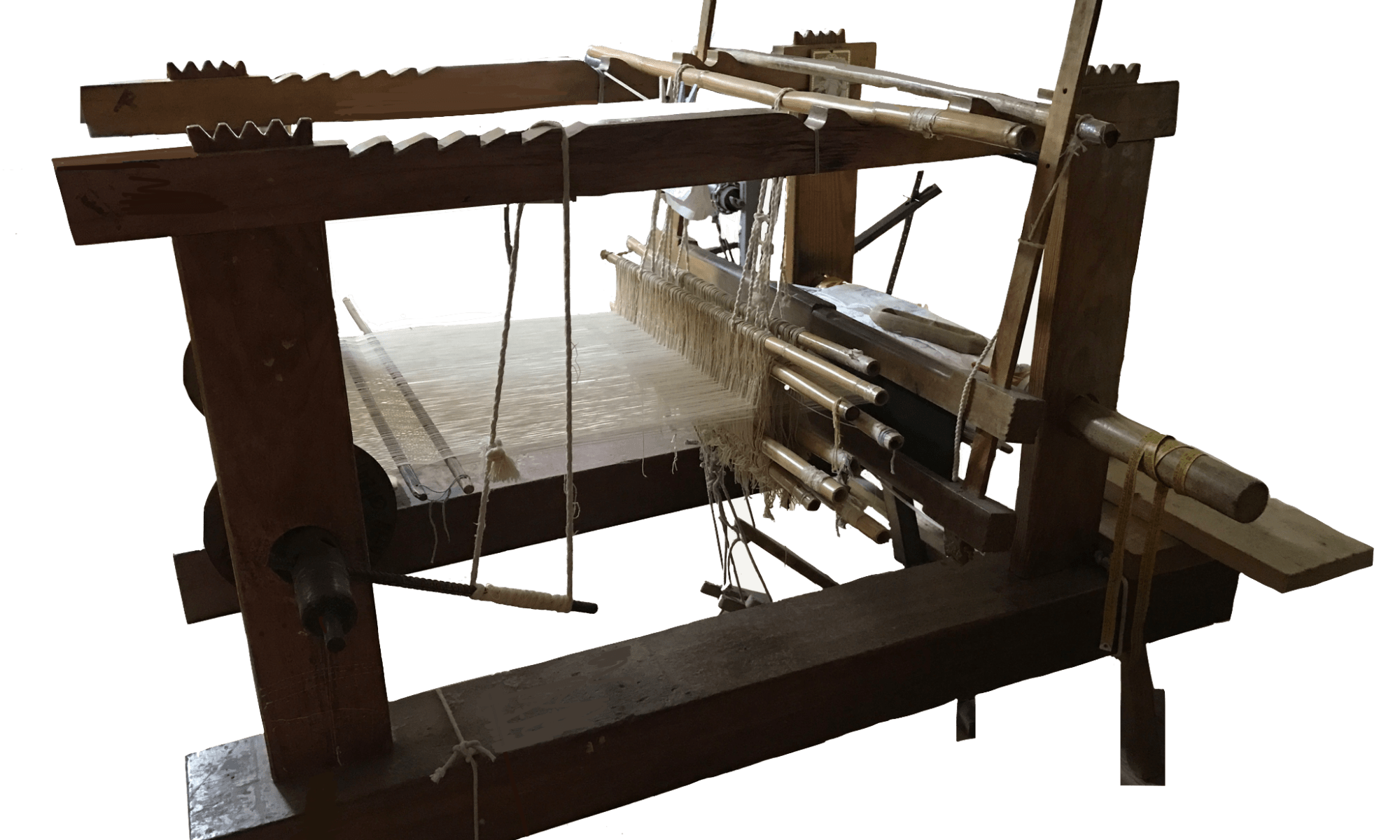

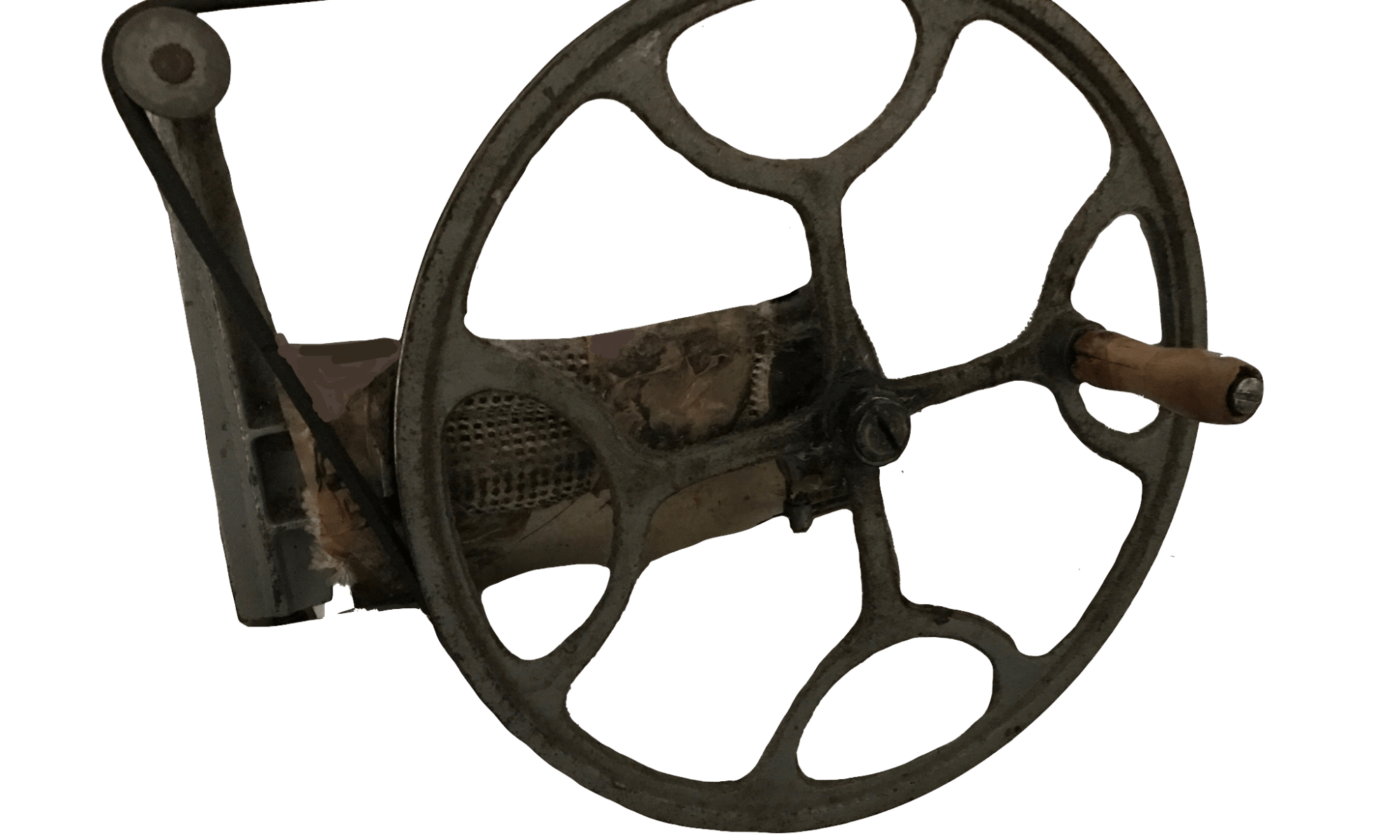

Handmade textiles: Textiles made completely by hand, using looms where all the movements and beating are done only by hand/foot, and not by a hydraulic, electronic, or computerized loom.

Hand-decorated textiles: Textiles made by hydraulic, electronic, or computerized looms, where all the beating is not done by hand/foot. The weavers stops the mechanical beating of the loom to make pibiones and/or add other decoration by hand.

Mill-made textiles: Textiles made in mills, by hydraulic, electronic, and/or computerized looms with minimum human involvement, and often where many similar objects are produced at the same time.

All the levels permit:

- The use of fibers prepared in mills.

- The use of a sewing machine, if the use is to make seams/hems after the weaving is cut from the loom and the seams/hems are not decorative.

- The use of fibers prepared by hand without hydraulic, electronic, or computerized tools can be indicated with the label “Hand-spun fibers”.

All three classifications have their buyers and their place in the market. There is no competition. The difference between the three classifications of textiles is the same as the difference between a painting by a master painter, a limited-edition print of the painting, and a poster.

Those who are able to purchase a handmade textile do so, just as those do who are interested and able to purchase an original painting by a well-know artist.

The people who admire the art and value high-quality, but are not able to afford the cost of articles that are entirely handmade are content to pay a good price for textiles made on powerlooms. In fact, I think that consumers will pay a higher price for articles made on powerlooms when high-end sellers perceive the weavers as representatives of an art, rather than only as producers of textiles. These buyers are like those who purchase limited edition prints of a painting.

Hotels, restaurant, and average users who want pillows, rugs, and curtains for daily use seek items that are not overly costly because they understand the items will be wear with constant use. Low-cost items produced in quantity — mill-made items — serve them well. In fact, commercially-made Sardinian textiles are of higher quality than most in the United States, and the label “Made in Sardinian” is of value. The buyers of these textiles are like those who purchase posters, commercially-printed representations of art.

The important elements are the recognition of the art and appreciation for the artist.

I sincerely believe that the method by which Sardinia can advance in a sustainable means in world commerce is to elevate and protect her arts. I think that it’s essential that the hand weavers are respected and are presented as artists who express a unique culture. This will benefit all the weavers, all the arts, and all the people of Sardinia. I firmly believe that when Sardinia offers the best of their own culture to the world, the world and all the people of Sardinia will derive the most benefit.

Kelly Manjula Koza

SardinianArts.com

© 2013 – 2025 Kelly Manjula Koza | All Rights Reserved